10

30

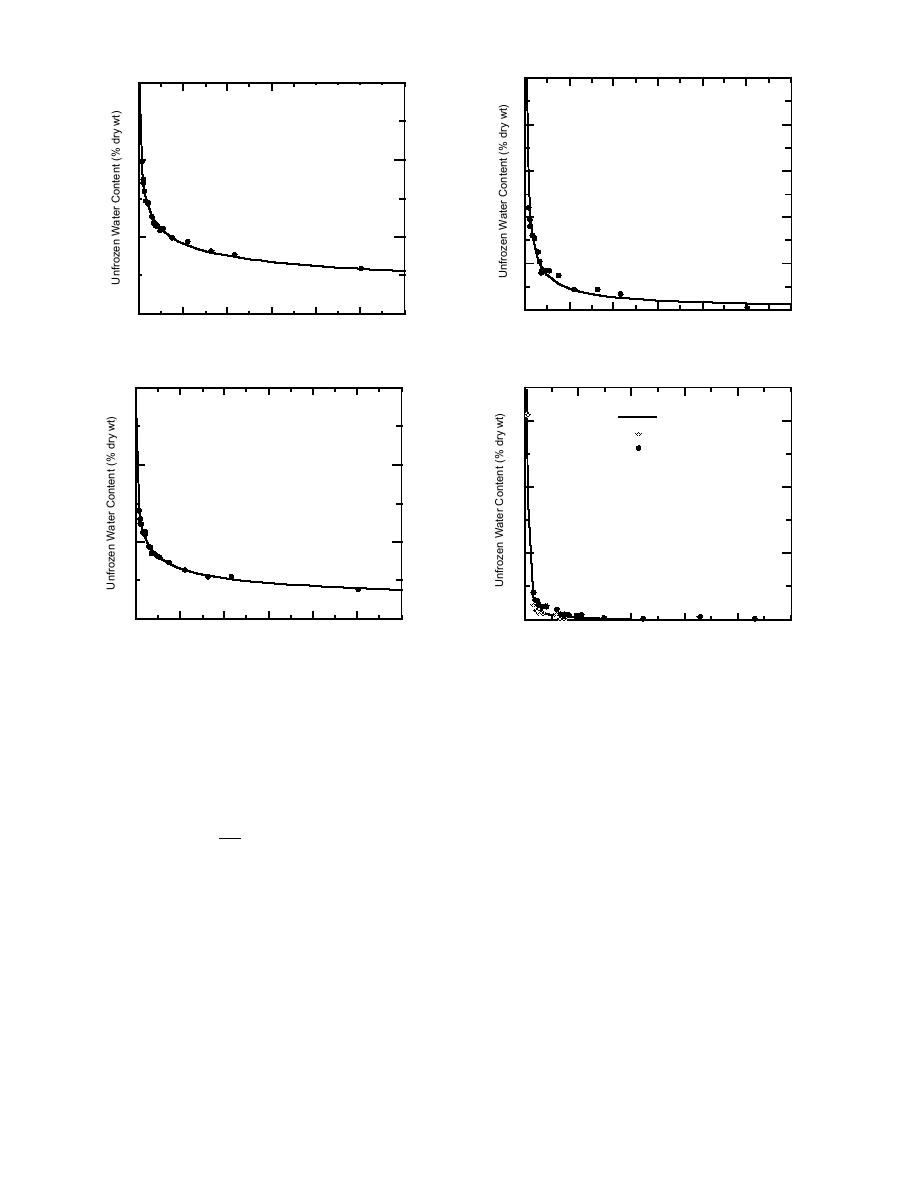

Class 3 Stockpile

Sample 1206

γd = 1.97 Mg/m3

γ = 1.23 Mg/m3

d

8

20

6

4

10

2

2

4

6

8

10

12

0

6

8

0

2

4

10

12

Temperature (C)

Temperature (C)

c. Class 3 stockpile.

a. Subgrade sample 1206.

30

Sample 1232

Class 6 Stockpile

γd = 1.53 Mg/m3

Calculated

30

+ No. 30; γd = 1.70 Mg/m3

- No. 30; γd = 1.85 Mg/m3

20

20

10

10

0

2

4

6

8

10

12

0

1

2

3

4

5

Temperature (C)

Temperature (C)

d. Class 6 stockpile.

b. Subgrade sample 1232.

Figure 13. Temperature vs. gravimetric unfrozen water content curves. Solid lines represent calculated

values used in the modeling.

the mechanistic procedure, produced with an equa-

Resilient modulus

tion in the form:

Laboratory resilient modulus tests were con-

ducted using repeated-load triaxial test procedures,

β

-T

the full details of which are described in Berg et

wu- g = α

; T < 0C

(4)

T0

al. (1996) and in Cole et al. (1986, 1987). The

tests involve applying a confining pressure to a

where wug = gravimetric unfrozen moisture con-

cylindrical specimen within a cell, while subject-

tent, %

ing the specimen to cyclical loading of a deviator

T = temperature, C

stress.

T0 = 1.0C

α, β = constants.

Test procedures--Mn/ROAD materials

The materials tested included the two extreme

Table 9 contains the constants determined for each

gradations of base--class 6 special and class 3

sample. Additional details about the procedure and

special, and the 1206 and 1232 subgrade samples

test results are in Bigl and Berg (1996a).

that represent, respectively, the high- and low-heav-

17

Previous Page

Previous Page