Portland Cement

Class 3 Special

Open Graded Base

Concrete

(with drain)

(cm)

(in.)

Class 4 Special

Class 5 Special

Class 6 Special

0

0

20

10

15

40

15

15

20

24

15

20

1.00

20

1.00

1.00

1.00

1.25

1.25

1.50

20

27

1.25

40

40

27

24

24

24

60

24

30

80

100

40

p = 20

d = 1.00

w = 27

120

50

R-5

R-6

R-7

R-8

R-9

R-10

R-11

R-12

R-13

5 Year Design Life

10 Year Design Life

a. 5-yr design life.

b. 10-yr design life.

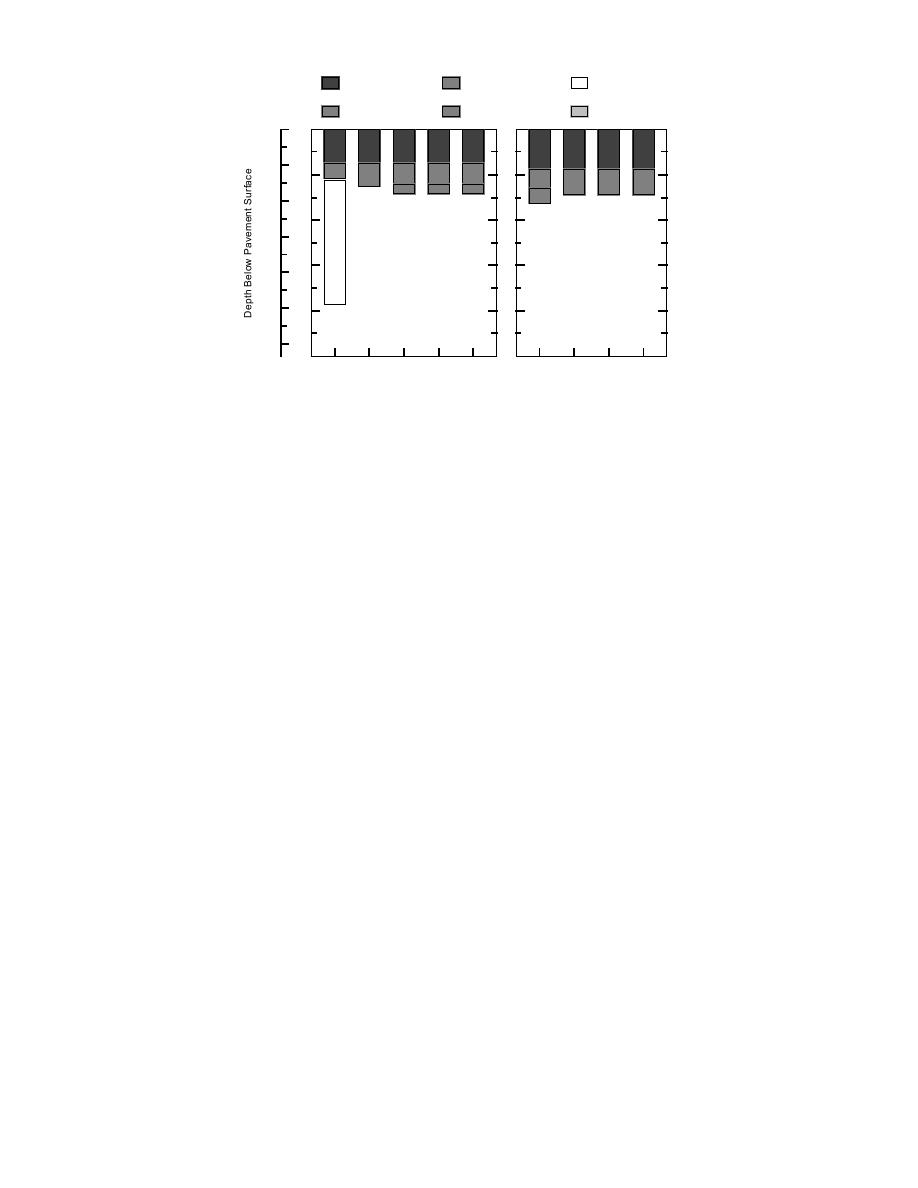

Figure 5. Mainline concrete test sections. In the figure, p refers

to panel length (ft), d--dowel diameter (in.), w--panel width (ft).

Supplemental steel rebar is included in the concrete of 5-year

section R-8.

class 5, class 4 and class 3, are all well-graded sands

through spring 1992. This effort, which included

with increasing amounts of finer size particles and

swamp excavation and backfill, and grading of

associated increasing frost susceptibility. Also in-

the test roadway to the top of the base materials,

required moving about 765,000 m3 (1,000,000 yd3)

cluded in one of the 10-yr sections is a porous

of material. Completion was significantly delayed

asphalt-stabilized open graded base. The subgrade

due to extremely wet weather during the 1990 and

beneath all test sections is a sandy lean clay. Bigl

1991 construction seasons.

and Berg (1996a) and Berg et al. (1996) detail

Stage 2 construction, which included paving

properties of the various materials at the site.

and installation of instrumentation, occurred dur-

In the concrete-surfaced test sections, param-

ing the 1992 and 1993 construction seasons. An

eters varied are the thickness of the concrete, panel

extensive period of sensor calibration, nondestruc-

width and length, dowel diameter, thickness and

tive pavement testing and collection of baseline

quality of underlying base materials, and pres-

data took place during winter 1993 and spring

ence of open-graded bases (Fig. 5). The concrete

1994. The test road was opened to traffic in Au-

paving surface is plain jointed concrete in all sec-

gust of 1994.

tions, with a constant thickness in the 5-yr and 10-

Three other reports have been prepared as part

yr sections. Panel lengths vary from 4.6 to 7.3 m

of this study (Bigl and Berg 1996a,b and Berg et

(15 to 24 ft); panel widths are 7.3, 8.2, or 12.2 m

al. 1996). This report summarizes the results of

(24, 27 or 40 ft). Dowel diameters are 2.5, 3.2 or

the other three. If additional details are desired or

3.8 cm (1, 1.25, or 1.5 in.). Base materials em-

needed, the other reports should be used.

ployed in the concrete sections are similar to those

used in the asphalt sections. The subgrade is also

a lean clay.

A number of different instrumentation types

MODEL DESCRIPTION

were installed at Mn/ROAD to measure the envi-

A mechanistic pavement design procedure is

ronmental conditions at the test sections, the traf-

being developed for use in seasonal frost areas

fic loadings, and the engineering behavior of the

and considers seasonal variations in pavement

materials.

strength such as:

Stage 1 construction took place June 1990

3

Previous Page

Previous Page