Asphalt Concrete

Open Graded Base

Class 3 Special

(cm)

(in.)

Class 4 Special

Class 5 Special

Class 6 Special

0

0

20

10

Low

VH

High

Low

40

VH

H

Low

20

H

60

Low

High

H

M

30

80

Low

L

Low

High

High

High

Low

100

H

M

H

VH

40

Low

L

H

Low

M

120

50

F-1

F-2

F-3

F-4

F-14

F-15

F-16

F-17

F-18

F-19

F-20

F-21

F-22

F-23

5 Year Design Life

10 Year Design Life

a. 5-yr design life.

b. 10-yr design life.

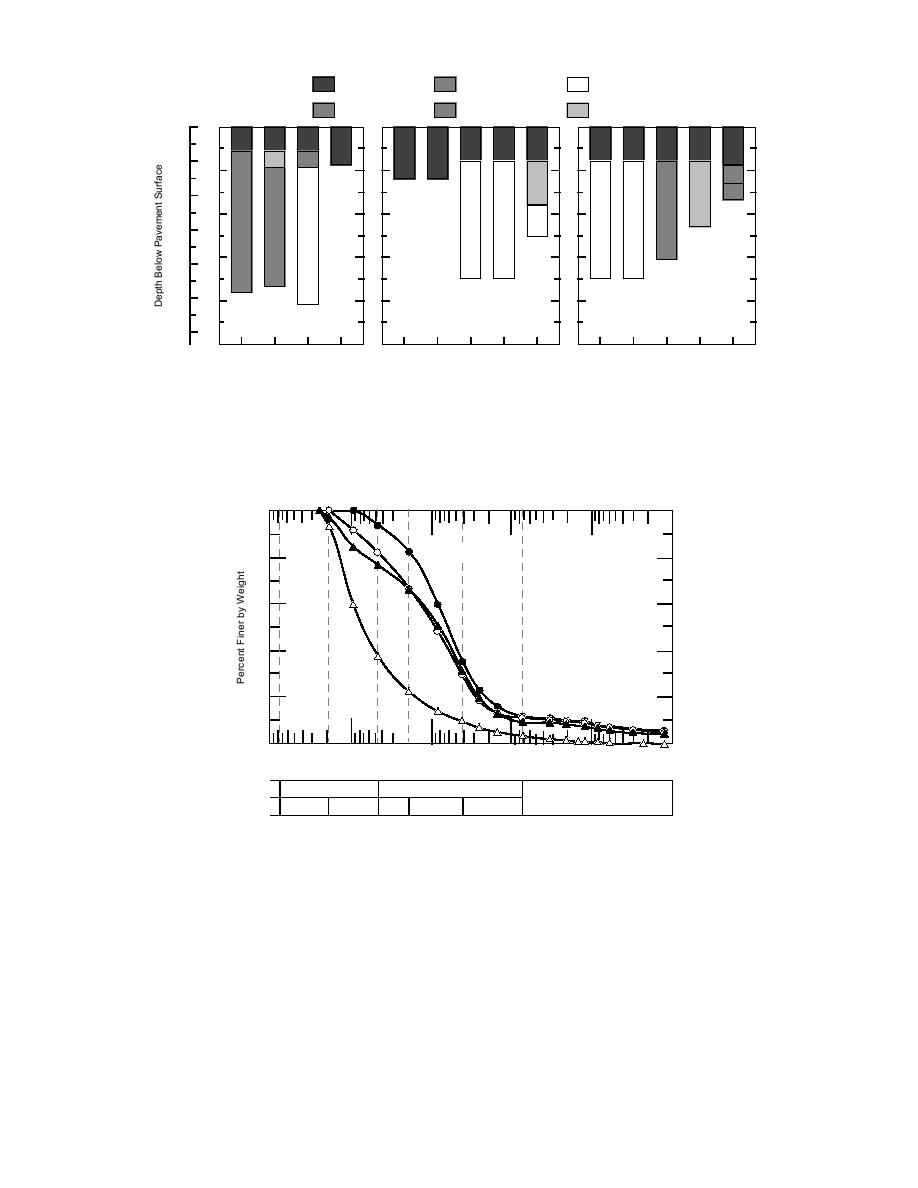

Figure 3. Mainline asphalt test sections. In the figure, beneath the base materials, High/

Low refer to the asphalt penetration viscosity number; design compactive effort is indicated

by VH--very high, H--high, M--medium, and L--low.

U.S. Std. Sieve Size and No.

Hydrometer

3/4

3

4

10

40

200

100

Class 3 Special

80

4

5

6

60

40

20

0

1.0

0.1

0.01

0.001

100

10

Grain Size (mm)

Gravel

Sand

Silt or Clay

C'rse

Fine

C'rse

Medium

Fine

Figure 4. Grain size distribution in tested specimens of Mn/ROAD

base materials.

Parameters included in the designs of the as-

PVN is more brittle. The design compactive effort

phalt test sections are the thickness and character-

applied to the asphalt also varies from low to very

istics of the asphalt surface and the presence, thick-

high, which resulted in varying asphalt cement

ness and quality of base materials (Fig. 3). The

contents in the field.

asphalt cement used was an 85/100 pen grade as-

The four granular base materials included in

phalt. The asphalt design included either of two

the test sections were specified and manufactured

temperature susceptibilities: one with a low pen-

to include a range in frost susceptibility (Fig. 4).

etration viscosity number (PVN) is characteristi-

The class 6 special is a relatively clean, non-frost-

cally more compliant and the other with a high

susceptible gravel with sand; the special bases,

2

Previous Page

Previous Page