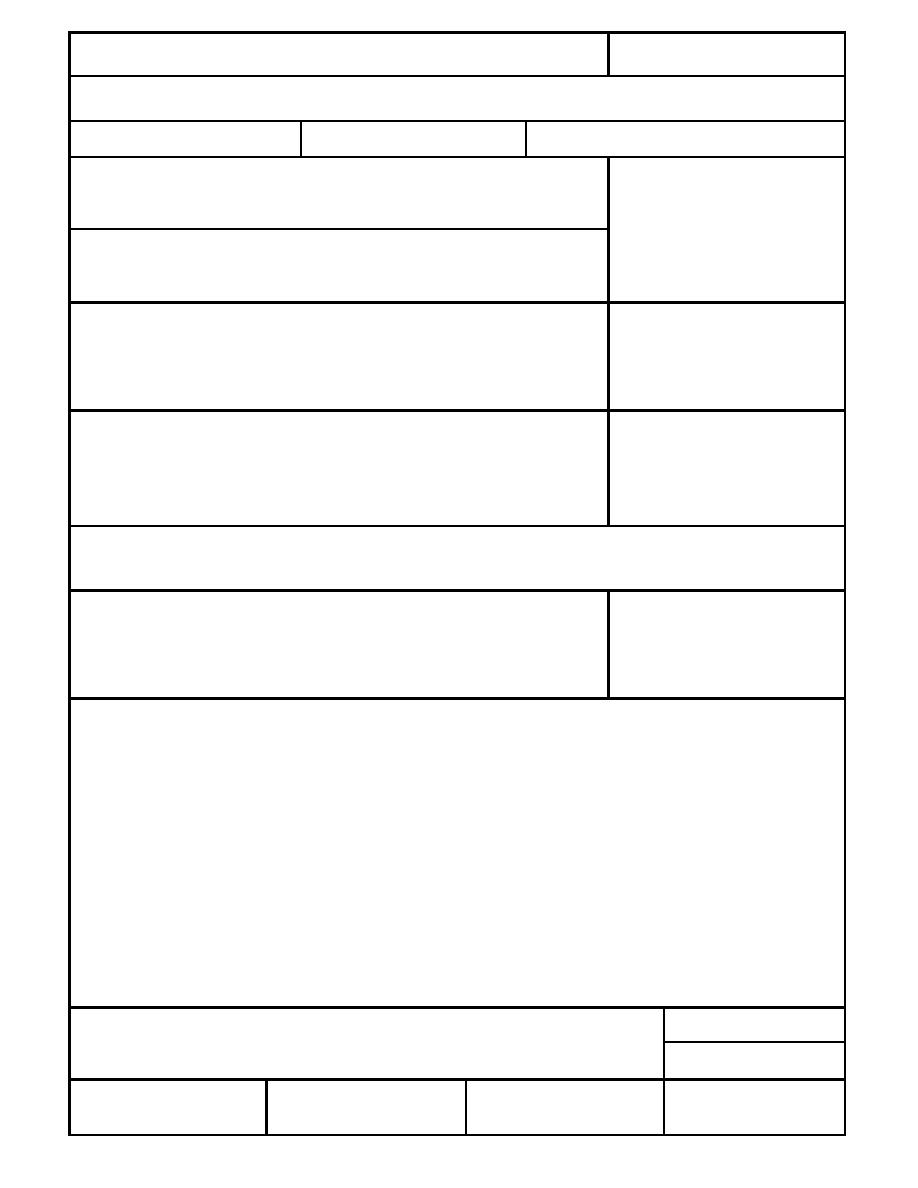

Form Approved

REPORT DOCUMENTATION PAGE

OMB No. 0704-0188

Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and

maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information,

including suggestion for reducing this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington,

VA 22202-4302, and to the Office of Management and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503.

1. AGENCY USE ONLY (Leave blank)

2. REPORT DATE

3. REPORT TYPE AND DATES COVERED

August 1996

4. TITLE AND SUBTITLE

5. FUNDING NUMBERS

Structural Mechanics Solutions for Butt Joint Seals in Cold Climates

PE: 6.27.84A

PR: 4A762784AT42

TA: BS

6. AUTHORS

WU: 020

Stephen A. Ketcham

7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

8. PERFORMING ORGANIZATION

REPORT NUMBER

U.S. Army Cold Regions Research and Engineering Laboratory

72 Lyme Road

CRREL Report 96-10

Hanover, New Hampshire 03755-1290

9. SPONSORING/MONITORING AGENCY NAME(S) AND ADDRESS(ES)

10. SPONSORING/MONITORING

AGENCY REPORT NUMBER

Office of the Chief of Engineers

Washington, D.C. 20314-1000

11. SUPPLEMENTARY NOTES

For conversion of SI units to non-SI units of measurement consult ASTM Standard E380-93, Standard Practice for Use of the

International System of Units, published by the American Society for Testing and Materials, 1916 Race St., Philadelphia, Pa.

19103.

12a. DISTRIBUTION/AVAILABILITY STATEMENT

12b. DISTRIBUTION CODE

Approved for public release; distribution is unlimited.

Available from NTIS, Springfield, Virginia 22161

13. ABSTRACT (Maximum 200 words)

An effective, formed-in-place joint seal will respond with elastic or viscoelastic behavior over a reasonable

design life to any large movement of the joint without adhesive or cohesive failure. For a given joint move-

ment, seals with lower stiffness are most able to deform without cohesive or adhesive failure of the seal or of

the structure to which it is bonded. It is in recognition of this desirable response feature that lower-modulus,

rubber-based elastomeric materials have been formulated and promoted as joint sealants. For a seal formed

from an elastomeric sealant, it should generally be expected that the modulus of elasticity will depend upon

temperature and loading rate, such that the modulus increases (sometimes dramatically) with a reduction in

temperature and an increase in loading rate, and it should be expected that the seal stiffness will depend upon

the material modulus and the shape of the seal. Measurements from testing techniques that are routinely used

to evaluate the temperature and rate-dependent mechanical properties of rubber-like materials, together with

simple structural mechanics solutions for the load vs. deflection behavior of rubber in the configuration of

rectangular-shaped joint seals, allow these dependencies to be modeled, and form the basis of a practical

analysis technique that could be used by civil and mechanical engineers for sealant selection and seal design.

14. SUBJECT TERMS

15. NUMBER OF PAGES

20

Elastomeric butt joint seal

Extension and compression loading

16. PRICE CODE

Shear loading

17. SECURITY CLASSIFICATION

18. SECURITY CLASSIFICATION

19. SECURITY CLASSIFICATION

20. LIMITATION OF ABSTRACT

OF REPORT

OF THIS PAGE

OF ABSTRACT

UNCLASSIFIED

UNCLASSIFIED

UNCLASSIFIED

UL

Standard Form 298 (Rev. 2-89)

NSN 7540-01-280-5500

Prescribed by ANSI Std. Z39-18

298-102

Previous Page

Previous Page