100

80

60

40

20

0

1.0

10

100

Diameter (mm)

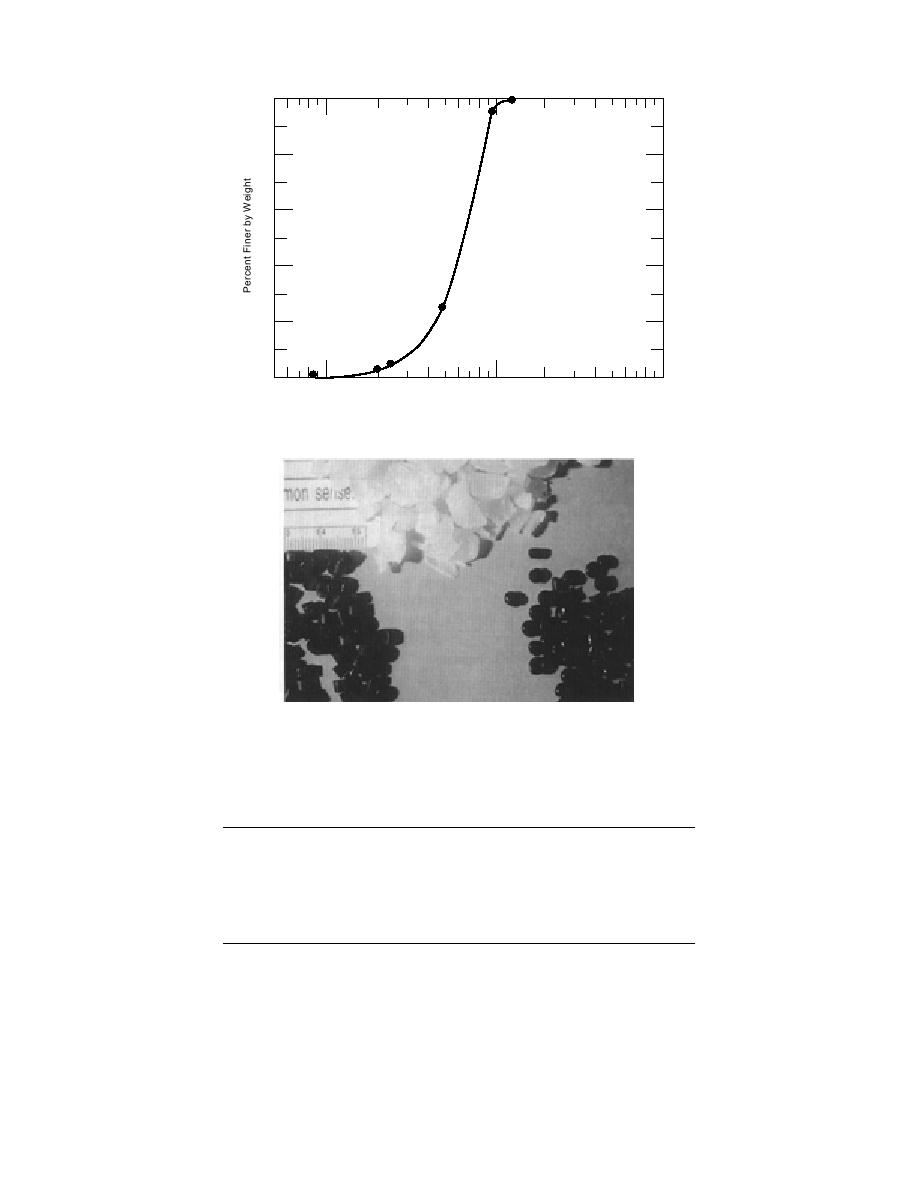

Figure 7. Size gradation of fractured polypropylene model ice material.

Figure 8. Model ice materials. Top: NYPA ice (polypropy-

lene). Bottom left: CRREL beads (polyethylene). Bottom right:

Iowa beads (polypropylene).

Table 2. Physical characteristics of plastic model ice particulates.

Characteristic

Iowa beads

CRREL beads

NYPA ice

Shape

Rods and discs

Squashed cylinders Angular

Size

D = 3 mm

L = D = 34 mm D50 = 6 mm

Angle of internal friction, φ

27

34

46

Passive failure coefficient, k1

2.66

3.54

6.13

Coefficient of lateral pressure, k0

0.55

0.44

0.28

Static friction coefficient, ξ

0.5

0.67

1.0

Overall,

0.73

1.04

1.78

Weakened ice

ing and developing breakable model ice materials.

Most weakened ices are thermally grown. The

An aim of that work has been to produce a model

weakening additives are included in the solution

ice that will facilitate small-scale modeling of large

from which the ice is grown, or are added to (e.g.,

structures, vessels, and ships. To date, severe scale

sprayed or sprinkled on) the ice as it grows. Two

limitations have required the use of large and very

other weakening techniques are also used. One

expensive refrigerated laboratories to accommo-

entails weakening by warming to reduce the

date such modeling.

11

Previous Page

Previous Page