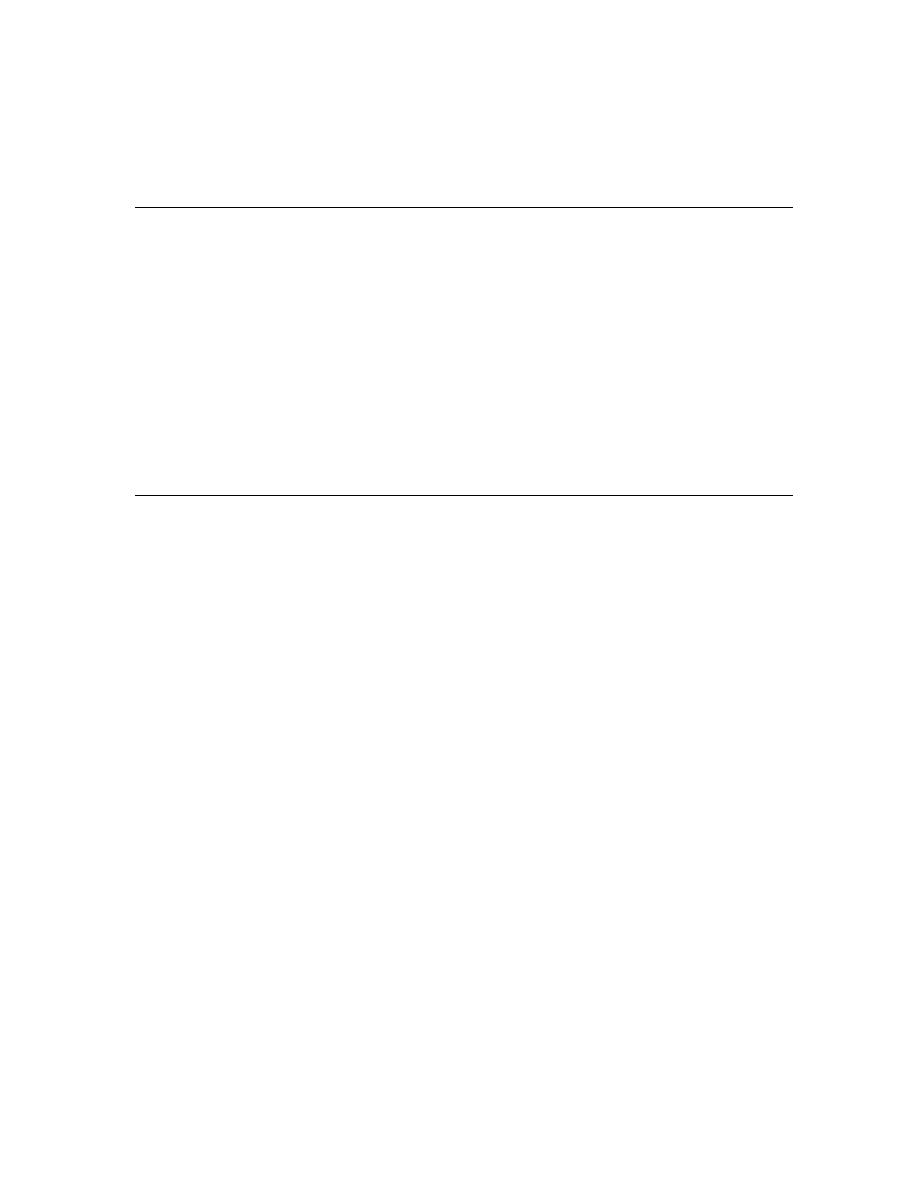

Table 13. Constraint satisfaction and costs for the remaining combinations. Our original design

(combination no. 1) is shown in bold, and the other feasible designs are shown in italic.

Cost

Comb. no.

d(6,7)

d(7,2)

d(7,3)

(h1)2

(h1)3

Variable

premium

(N/m2)

(N/m2)

costs ($)

(%)

and type

(m)

(m)

(m)

1 (0,0,0)

0.1071

0.0703

0.0703

96,183

50,374

38,002

0

3 (0,0,)

0.1071

0.0703

0.0545

96,183

193,207

35,435

6.76

7(0,,0)

0.1071

0.0545

0.0703

25,607

50,374

36,718

3.38

9(0,,)

0.1071

0.0545

0.0545

25,607

193,207

34,151

10.13

12(+,0,)

0.1325

0.0703

0.0545

123,482

165,908

39,480

3.89

15(+,+,)

0.1325

0.0825

0.0545

149,022

165,908

40,464

6.48

16(+,,0)

0.1325

0.0545

0.0703

1,692

77,673

40,764

7.27

17(+,,+)

0.1325

0.0545

0.0825

1,692

128,753

42,732

12.45

18(+,,)

0.1325

0.0545

0.0545

1,692

165,908

38,196

0.51

19(,0,0)

0.0825

0.0703

0.0703

18,468

64,278

34,058

10.38

20(,0,+)

0.0825

0.0703

0.0825

18,468

13,198

36,027

5.20

21(,0,)

0.0825

0.0703

0.0545

18,468

307,859

31,491

17.13

22(,+,0)

0.0825

0.0825

0.0703

7,071

64,278

35,042

7.79

23(,+,+)

0.0825

0.0825

0.0825

7,071

13,198

37,011

2.61

24(,+,)

0.0825

0.0825

0.0545

7,071

307,859

32,475

14.54

25(,,0)

0.0825

0.0545

0.0703

140,259

64,278

32,774

13.76

26(,,+)

0.0825

0.0545

0.0825

140,259

13,198

34,743

8.58

27(,,)

0.0825

0.0545

0.0545

140,259

307,859

30,207

20.51

status of the two consumer constraints that must be satisfied and the total of the

variable portions of the capital costs and heat loss costs for each combination. We see

by examining the constraint satisfaction that only two combinations are feasible, i.e.,

they satisfy the h1 constraint for both consumers 2 and 3. However, when we

calculate the cost of these feasible combinations, we find that both cost more than our

original design. Thus, we are left with the result that none of the alternatives

investigated so far are better than our original design. There are some additional

designs that we have not investigated, however. Recall that earlier we dismissed the

possible designs that would increase or decrease pipe sizes by more than one

discrete size from the original design. Depending on how many pipe sizes we are

willing to deviate from our original design, there are many alternate designs. Of

course, there is no guarantee that these designs will be feasible, let alone lower in cost

than the original design. To explore these designs without resorting to "exhaustive

enumeration," i.e., calculating the constraint satisfaction and cost of each, we can use

the branch-and-bound technique described in detail in Chapter 5. Below we apply

this technique to our example problem. In the process of doing so, we will not only

explore additional designs not considered yet, but we will show how the technique

would have allowed us to dismiss some of the alternatives in Table 13 without

computing the constraint satisfaction or total variable cost.

As noted in the previous chapter, the objective of the branch-and-bound tech-

nique is to use what is known about designs already explored to reduce the number

of remaining ones that must be examined in detail. In addition, we would like to do

so without dismissing any designs superior to the best feasible ones identified. We

have effectively already used the technique above to dismiss nine of the possible

combinations of Table 12. In that case, we used the fact that the variable portions of

the heat losses and capital pipe costs were monotonically increasing in pipe

diameter. This allowed us to dismiss cases that only increased pipe size.

After our initial elimination of nine combinations, as discussed above, we see that

69

Previous Page

Previous Page