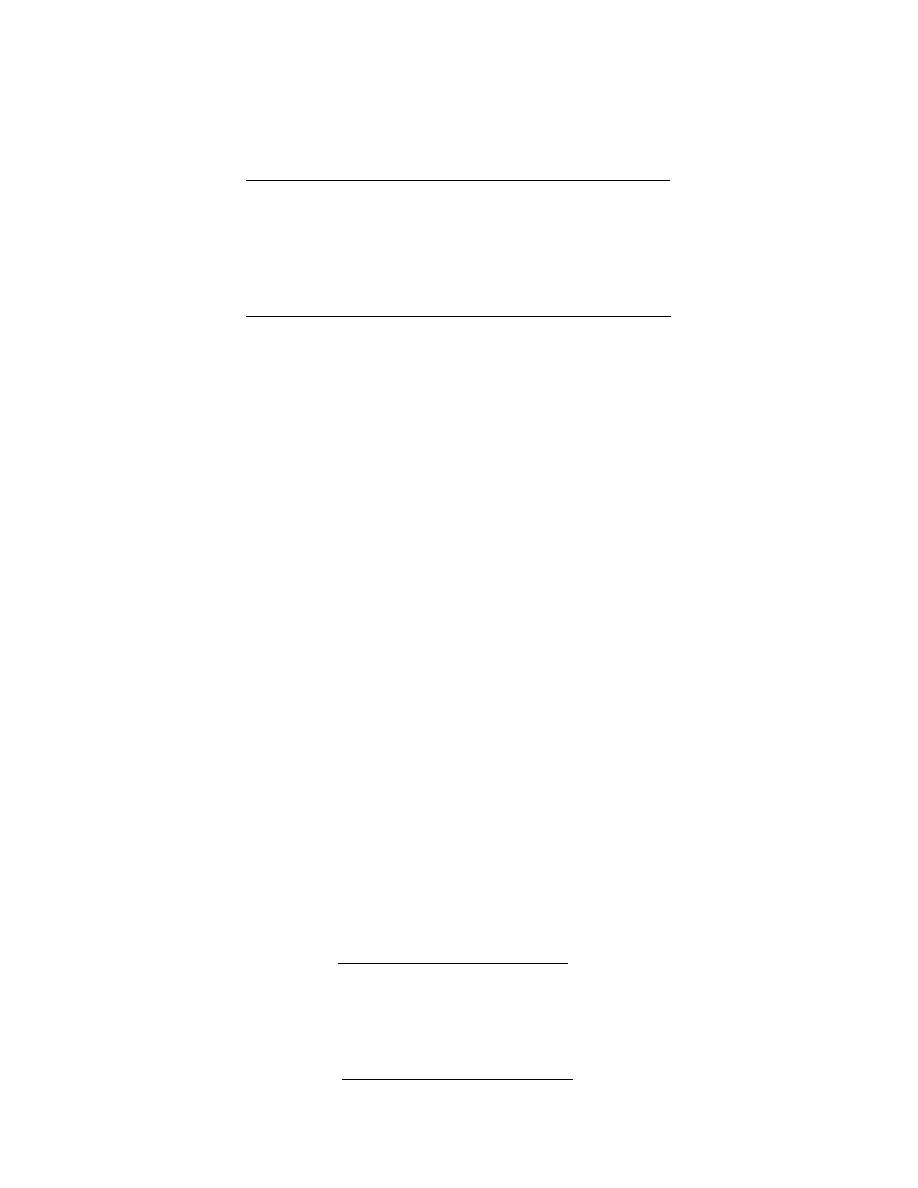

Table 5. Assigned values for nodes of example in Figure 14.

Node

Elevation

Maximum demand

number

Node type

(m)

(kg/s)

1

heat consumer

40

10

2

heat consumer

30

10

3

heat consumer

20

10

4

heat consumer

10

10

5

pipe junction

0

--

6

pipe junction

0

--

7

pipe junction

0

--

8

heating plant

0

40

Now we proceed to find the optimal pipe diameters for our example system of

Figure 14. As we found in the last chapter, a convenient starting point is what we will

call the "optimal independent design." This is the design that we would arrive at if

we use the procedure developed in Chapters 2 and 3 for each pipe segment as if it

were independent of the others and its design were unconstrained by the system

constraints identified in Chapter 4. We will make use of all of the assumptions for

parameter values and operating strategy that we used in the examples of Chapters

2 and 3. For clarity these are repeated below:

Am&r = 2%/yr

Aη = 0.90 (dimensionless)

A1 = 60/pump

A2 =

||content||

.242/WA3 = 8

A4 = 80/m

A13 = 1.0 (dimensionless)

A14 = 0.575 (dimensionless)

A15 = 0.425 (dimensionless)

Tm = 6.4C

ki = 0.030 W/m C

ks = 1.3 W/m C

Hp = 1.0 m

xi = 0.050 m

Table 6. Assigned values for the

pipe segments in the example of

Figure 14.

Elevation Maximum

Pipe

Length

change

flow

segment

(m)

(m)

(kg/s)

6,1

100

40

10

7,2

25

30

10

7,3

50

20

10

5,4

100

10

10

6,7

50

0

20

5,6

100

0

30

8,5

200

0

40

63

Previous Page

Previous Page