centrifuge. Manual operation was necessary be-

8-g and 32-g tests along with the corresponding

cause of the crude response of the centrifuge's

1-g prototype values calculated using either the

refrigeration control system. The duration of the

Table 1 scale factors or the scaling process de-

experiments was approximately five hours. A ther-

scribed in Appendix B. The temperature records

mocouple located at the top of the closed centri-

reveal that the chamber temperature varied by

0.25C from the desired temperature of 2C.

fuge chamber provided the only temperature

measurement for the tests. There was no measure-

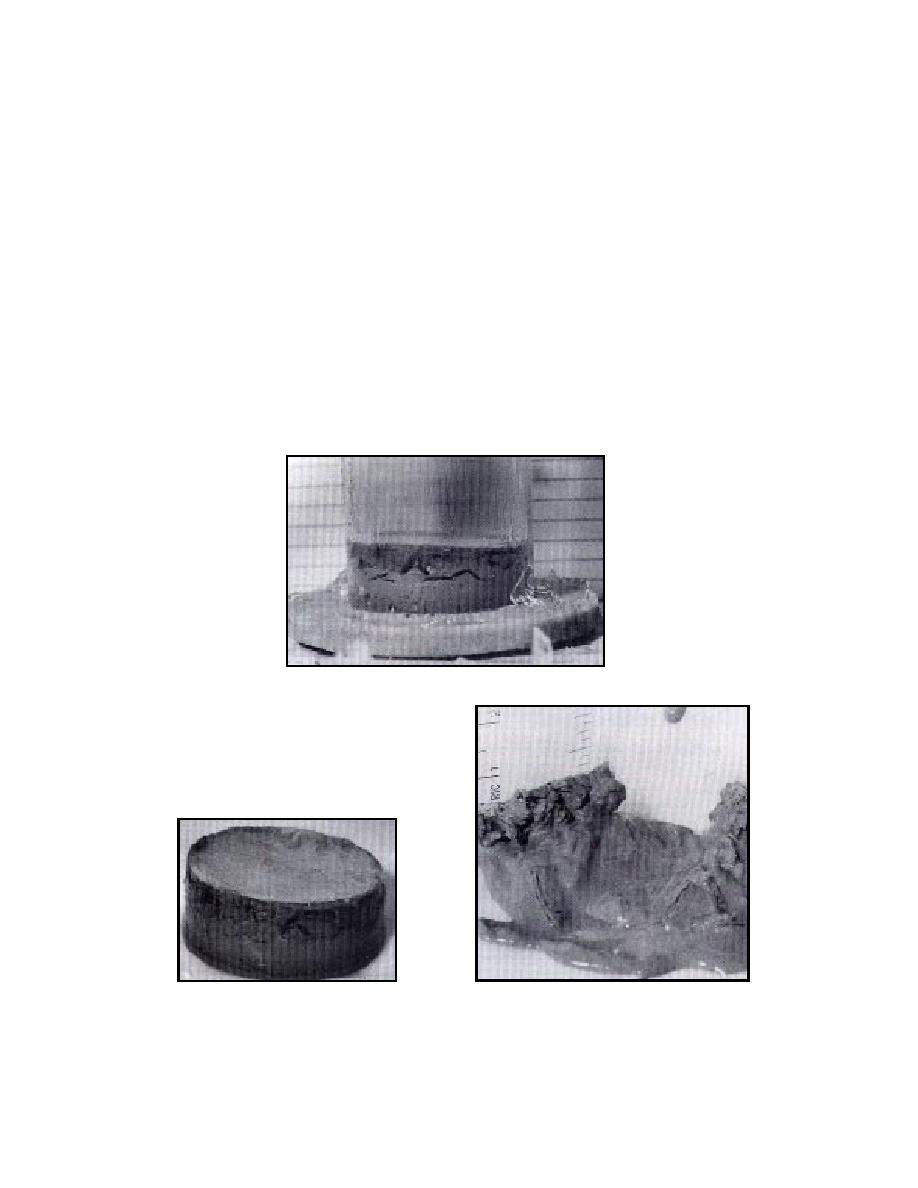

Figures 4 and 5 show the 8-g and 32-g samples,

ment of the temperature of the sample. In addi-

respectively, before and after their extrusion from

tion there was no measurement of the sample

the cylinder and after crudely cutting them to

heave as a function of time.

examine the interior ice lens configuration. The

air temperature surrounding the samples during

cutting was 4.5C. As a result the figures show

the samples in progressive stages of melting.

RESULTS

In the five-hour test period, only the upper 5

The experimental data consist of measurements

8 mm of the 8-g and 32-g samples froze. This was

of the temperature in the centrifuge chamber, mea-

a desired result, as it confirms that the freezing

surements of the height of the samples at the be-

occurred from the top down. This was important

ginning and end of the tests, and observations

since we had no other means of monitoring the

and photographs of the samples following the

progress of the freezing front. That the 8-g and

tests. Table 2 presents the measurements for the

32-g samples would freeze to about the same depth

a. Prior to extrusion from the cylinder.

b. After extrusion from the cylinder.

c. After cutting to examine the interior ice lens

configuration.

Figure 4. Sample used in the 8-g experiment.

5

Previous Page

Previous Page