ed on a porous plastic base to allow water flow to

der of the assembled sample container. The nomi-

the sample from an exterior annular reservoir. Ex-

nal sample dimensions were 10 mm in height and

cept for the upper end of the Plexiglas cylinder,

34 mm in diameter. We prepared each sample at

the cylinder and reservoir were surrounded by

room temperature by mixing 12.5 g of the New

insulation. The upper end of the cylinder was left

Hampshire silt with water to form a slurry with

open to the air. The insulated sample containers

an 80% water content. The slurry was poured into

were made to fit into cylindrical cups that were

the Plexiglas cylinder, preloaded and consolidated

supplied with the centrifuge. These cups have

with a vertical stress of 14.1 kPa. Free water ex-

inside dimensions of 98 mm in diameter and 120

pelled at the sample surface was removed. The

mm in height.

dry mass density of the consolidated samples was

approximately 2040 kg/m3. The sample contain-

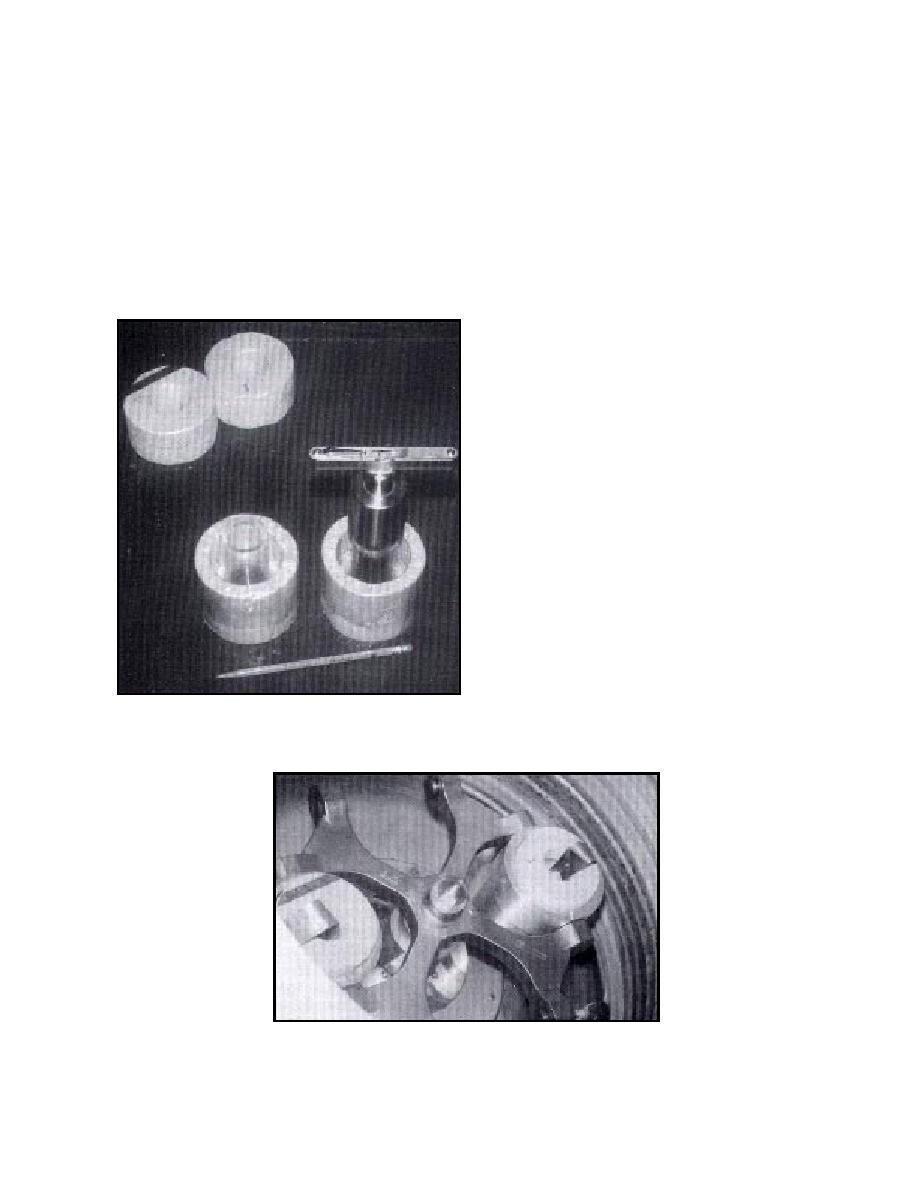

The test samples comprised a saturated New

Hampshire silt compacted in the Plexiglas cylin-

ers and sample preloading equipment are shown

in Figure 2.

Following the sample preparation, the in-

sulated sample containers were taken to the

coldroom, placed in the centrifuge cups, and

immediately tested. Figure 3 shows the sample

containers in the centrifuge. The radius from

the centrifuge axis to the sample bottom was

0.196 m. To achieve nominal gravity levels of

8 and 32 g at desired reference radii in the tests

(Cooke 1991), the centrifuge was operated at

rotational velocities close to 193 and 387 rpm,

respectively. The effect of Earth's gravity on the

equilibrium orientation of the centrifuge cups was

considered in our calculation of these velocities.

The experiments were conducted with mini-

mal control of the temperature of the sample

and with minimal measurement of the sample

response. Our hope for these preliminary ex-

periments was simply that we could freeze the

samples from the top down. We operated the

centrifuge with the centrifuge chamber closed

to the coldroom atmosphere, and we main-

tained the chamber temperature close to our

desired temperature of 2C by manually turn-

Figure 2. Sample containers and sample preloading equip-

ment.

ing on and off the refrigeration system of the

Figure 3. Sample containers in the centrifuge.

4

Previous Page

Previous Page