ous solutions of saturated sodium chloride. Both types

and in some places (along edges) the plating became

of metal coupons were then repeatedly heated to tem-

friable.

peratures greater than 1100F (593C). This size cou-

pon is large enough to hold a 5-L aliquot of acetoni-

Stock solutions of TNT, RDX, and HMX

The solubility of TNT in acetone is about 109 g per

trile or acetone on the surface during spiking, yet small

100 g at 20C, and the solubility is nearly as high in

enough to fit into, and lie flat on the bottom of, a stan-

acetonitrile. A concentrated stock solution was prepared

dard 40- or 20-mL VOA vial for residue recovery. When

by dissolving 1 g of TNT into 5 mL of acetonitrile (0.2

in this position (lying flat on the bottom of the vial),

g TNT/mL).

the coupon is submersed in 1 mL of extraction solvent.

The solubility of RDX in acetonitrile is about 12 g

per 100 g at 30C. To prepare a concentrated stock so-

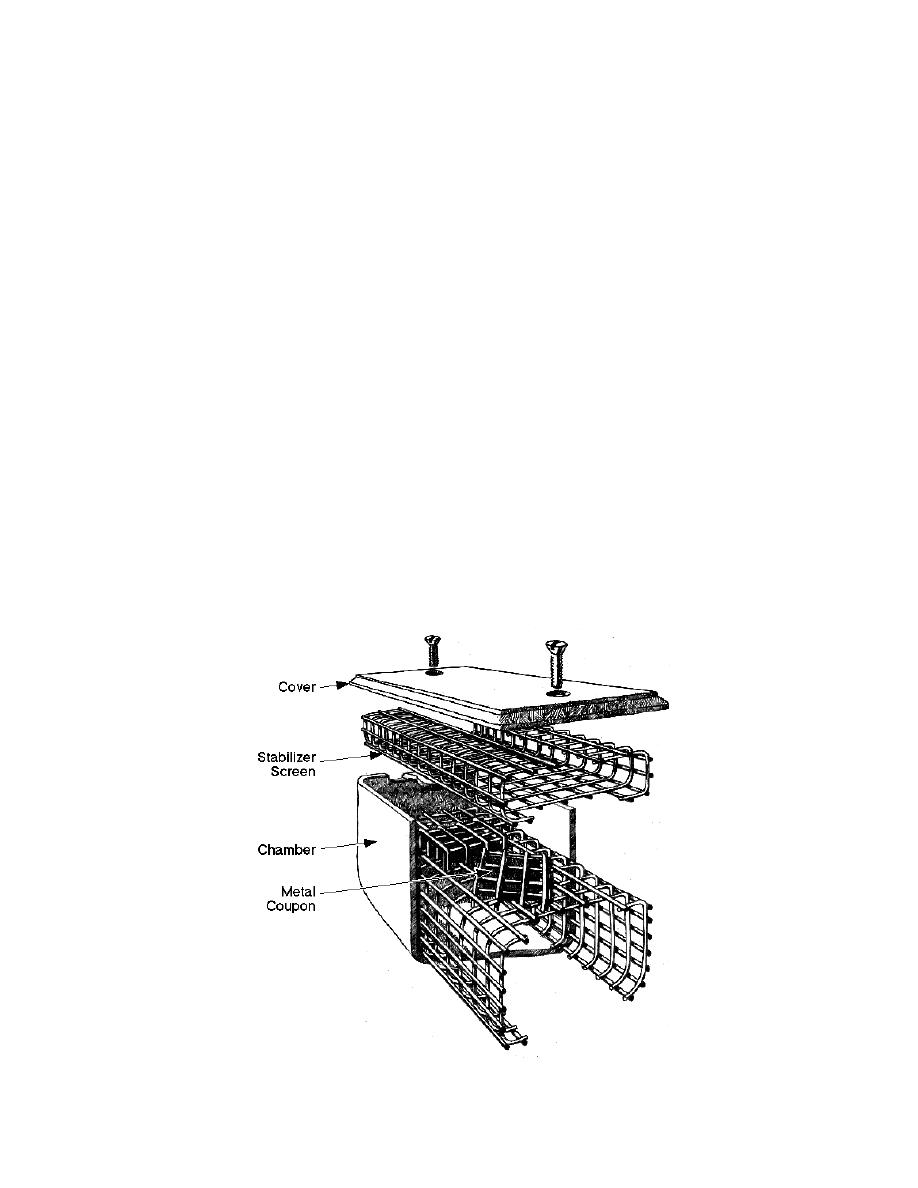

Chambers

lution for RDX, 1 g was dissolved into 25 mL of aceto-

Chambers for housing one or more coupons (e.g.,

nitrile (0.04 g RDX/mL).

an aluminum and steel coupon), a small piece of range

The solubility of HMX in acetonitrile is about 2 g

scrap, and perhaps a thermocouple, were made from

per 100 mL. To prepare a concentrated stock solution,

standard zinc-plated-steel electrical switch boxes (Fig.

0.1 g was dissolved in 5 mL of acetonitrile (0.02 g HMX/

1). These boxes had four 4.7-mm holes in the bottom,

mL). Several of the larger crystals (0.25 0.25 mm) of

and had an additional 4.7-mm hole drilled into each of

the four side walls. Zinc-coated wire fencing (6.4 6.4

HMX did not dissolve when this stock solution was

prepared, so a concentration lower than 0.02 mg/L was

mm) was molded into platforms to hold coupons firmly

anticipated.

near the center of the chamber, while leaving space for

a small (less than 2.5 5 2.5 cm [h, l, w]) piece of

All stock solutions were transferred to amber glass

range scrap. If necessary, a thermocouple could also be

bottles with Teflon-lined septum screw caps that were

stored at room temperature. Periodically, the threads of

located within the chamber by removing one of the

these bottles needed to be wiped with a solvent-moist-

knock-out tabs and using a standard metal wire lock to

ened towel to remove a deposit of crystals. The forma-

secure the wire lead. This chamber and wire mesh cage

did not physically deform when exposed to 1100F

tion of crystals and difficulties encountered in the prepa-

(593C) for 6 hours. However, this thermal treatment

ration of these concentrated solutions were two

unforeseen problems that should be addressed in the

did turn the zinc plating to a white or yellowish color,

Figure 1. Chamber for housing one or more coupons.

3

Previous Page

Previous Page