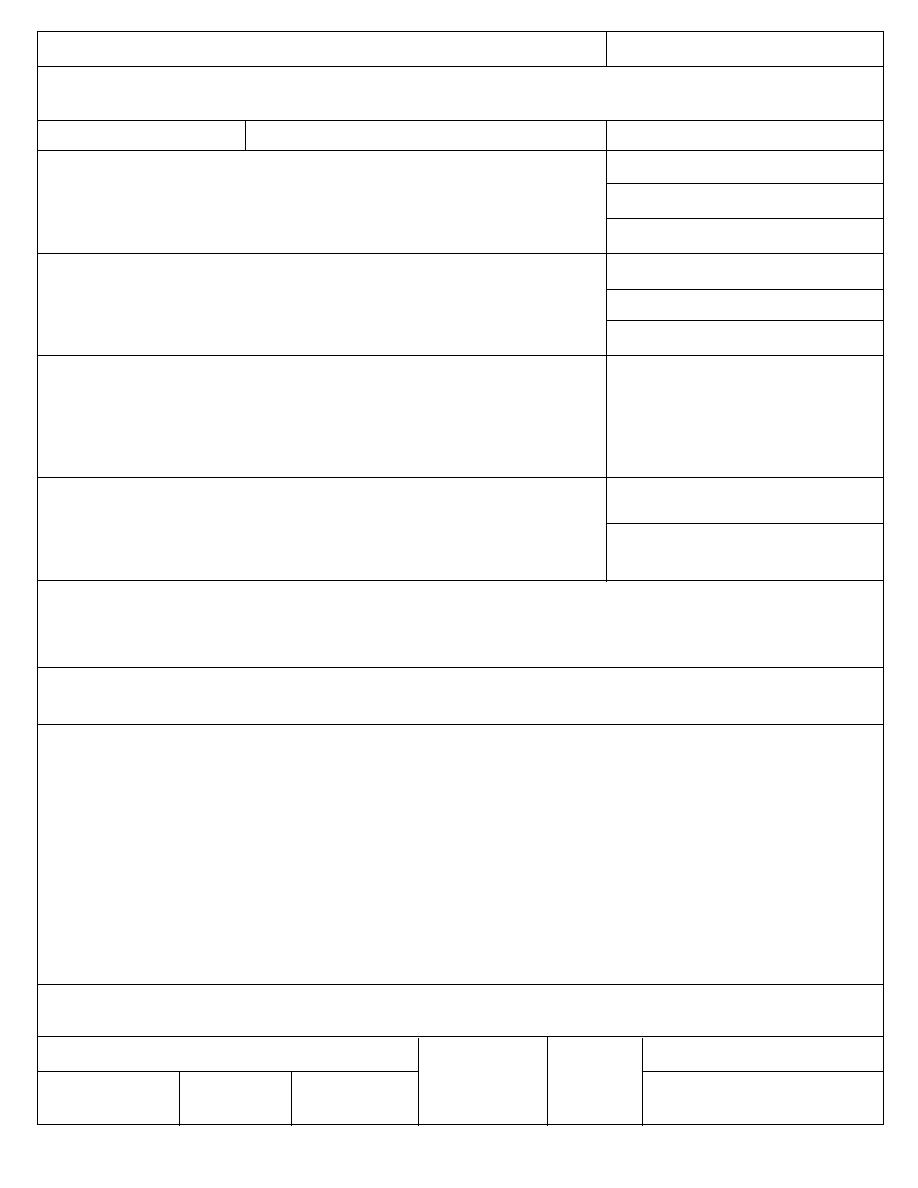

Form Approved

REPORT DOCUMENTATION PAGE

OMB No. 0704-0188

Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the

data needed, and completing and reviewing this collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing

this burden to Department of Defense, Washington Headquarters Services, Directorate for Information Operations and Reports (0704-0188), 1215 Jefferson Davis Highway, Suite 1204, Arlington, VA 22202-4302.

Respondents should be aware that notwithstanding any other provision of law, no person shall be subject to any penalty for failing to comply with a collection of information if it does not display a currently valid

OMB control number. PLEASE DO NOT RETURN YOUR FORM TO THE ABOVE ADDRESS.

1. REPORT DATE (DD-MM-YY)

2. REPORT TYPE

3. DATES COVERED (From - To)

August 2001

Technical Report

4. TITLE AND SUBTITLE

5a. CONTRACT NUMBER

5b. GRANT NUMBER

A Method for Producing Fine-Grained Ice from Snow Compaction

5c. PROGRAM ELEMENT NUMBER

6. AUTHOR(S)

5d. PROJECT NUMBER

Deborah Diemand and Valery Klokov

5e. TASK NUMBER

5f. WORK UNIT NUMBER

7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

8. PERFORMING ORGANIZATION REPORT

NUMBER

U.S. Army Engineer Research and Development Center

Cold Regions Research and Engineering Laboratory

72 Lyme Road

ERDC/CRREL TR-01-12

Hanover, New Hampshire 03755-1290

9. SPONSORING/MONITORING AGENCY NAME(S) AND ADDRESS(ES)

10. SPONSOR / MONITOR'S ACRONYM(S)

Office of the Chief of Engineers

Washington, DC 20314

11. SPONSOR / MONITOR'S REPORT

NUMBER(S)

12. DISTRIBUTION / AVAILABILITY STATEMENT

Approved for public release; distribution is unlimited.

Available from NTIS, Springfield, Virginia 22161.

13. SUPPLEMENTARY NOTES

14. ABSTRACT

This report describes a preliminary study of the fabrication of building blocks by converting snow directly to ice without the very high energy

cost of melting it first. This was accomplished by a hot sinter technique that produced a very fine-grained material that is considerably

stronger than natural ice. The very high pressures applied to the snow appear not only to have reduced the grain size present in the raw

material (natural snow), but to have completed the sintering process before the block was removed from its form, as there was no convincing

increase in strength at any storage temperature over a period of 20 days, nor were there any striking crystallographic changes.

15. SUBJECT TERMS

Fine-grained ice

Hot pressing

Snow compaction

High-pressure compaction

Snow bricks

Snow construction

16. SECURITY CLASSIFICATION OF:

17. LIMITATION OF

18. NUMBER

19a. NAME OF RESPONSIBLE PERSON

OF ABSTRACT

OF PAGES

a. REPORT

b. ABSTRACT

c. THIS PAGE

19b. TELEPHONE NUMBER (include area code)

U

U

U

U

43

Standard Form 298 (Rev. 8-98)

]Prescribed by ANSI Std. 239.18

Previous Page

Previous Page