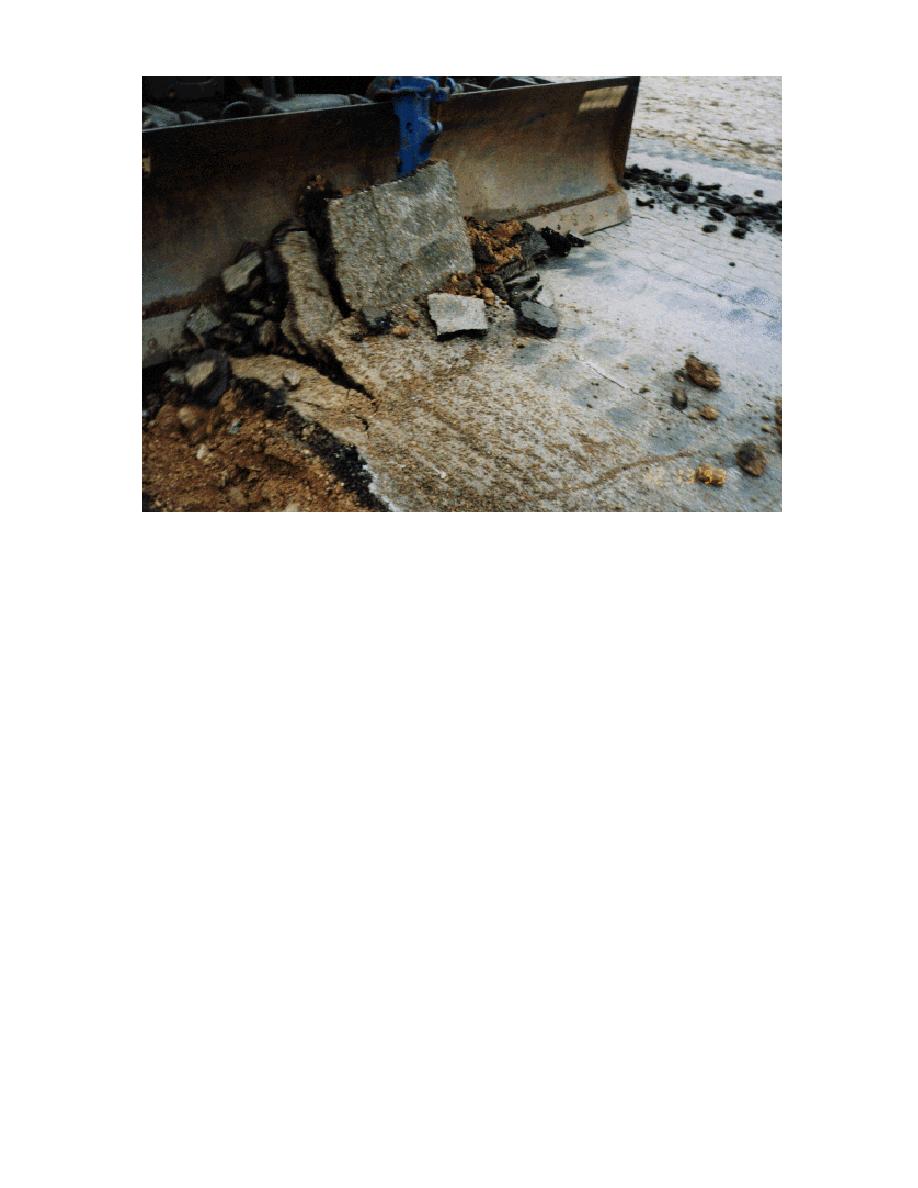

Figure 11. Ripper shown at full penetration in asphalt pavement with the blade sliding along the pavement

surface. The slots cut during the previous passes are similar to those produced in thin seasonal frost.

school (Fig. 11). At no time was ripping resistance

planned depth. In hard ground, maintaining the

great enough to cause track slip or any significant

depth was a problem, since tooth configuration

motion in the suspension of the machine. Ripping

and variations in material properties tended to

this thin frost seemed effortless.

cause large fluctuations in the vertical force re-

In contrast, ripping at the site with thick frost

quired to control the ripper. The ripper would

was noticeably different, with much greater resis-

tend to grab and pull into the ground, loading the

tance to ripper advance. Ripping to the depth of

suspension system. This would result in the rip-

the ripper (14 in. [36 cm]) usually required three

per cutting a deeper groove, which could slow

passes. Ripping forces were also great enough to

forward progress and occasionally stop the ma-

affect traction and cause significant interaction

chine. Attempts to respond by pulling up the blade

with the suspension. As with the commercial trac-

only compressed the suspension further until suf-

tors, the best performance was obtained when

ficient vertical force was available to pull the rip-

passes were made parallel to a cut ripped to full

per up, out of the ground; sometimes the ripper

depth, which provides an additional free face for

jumped to a position above the ground surface

material failure. The large size of the frozen blocks

when the suspension unloaded. It was not pos-

produced can be seen in Figure 12. Since ripping

sible to fine tune the depth of cut as it was with

to full depth required successive passes, it was

the commercial tractors that have no suspension

necessary to hold the blade in a position that

system. However, careful teamwork between the

would permit incremental penetration.

operator and the spotter on the ground and good

Initial penetration was not difficult, and Figure

operating technique can reduce this problem and

12 shows the CEV starting a pass while holding

maintain productive ripping.

the blade in a position that would allow 6 to 8 in.

A technique that worked well was based on

(15 to 20 cm) of penetration. Very little down

responding to changes in forward progress. Once

pressure on the blade was required to reach the

the operator sensed that forward progress was

11

Previous Page

Previous Page