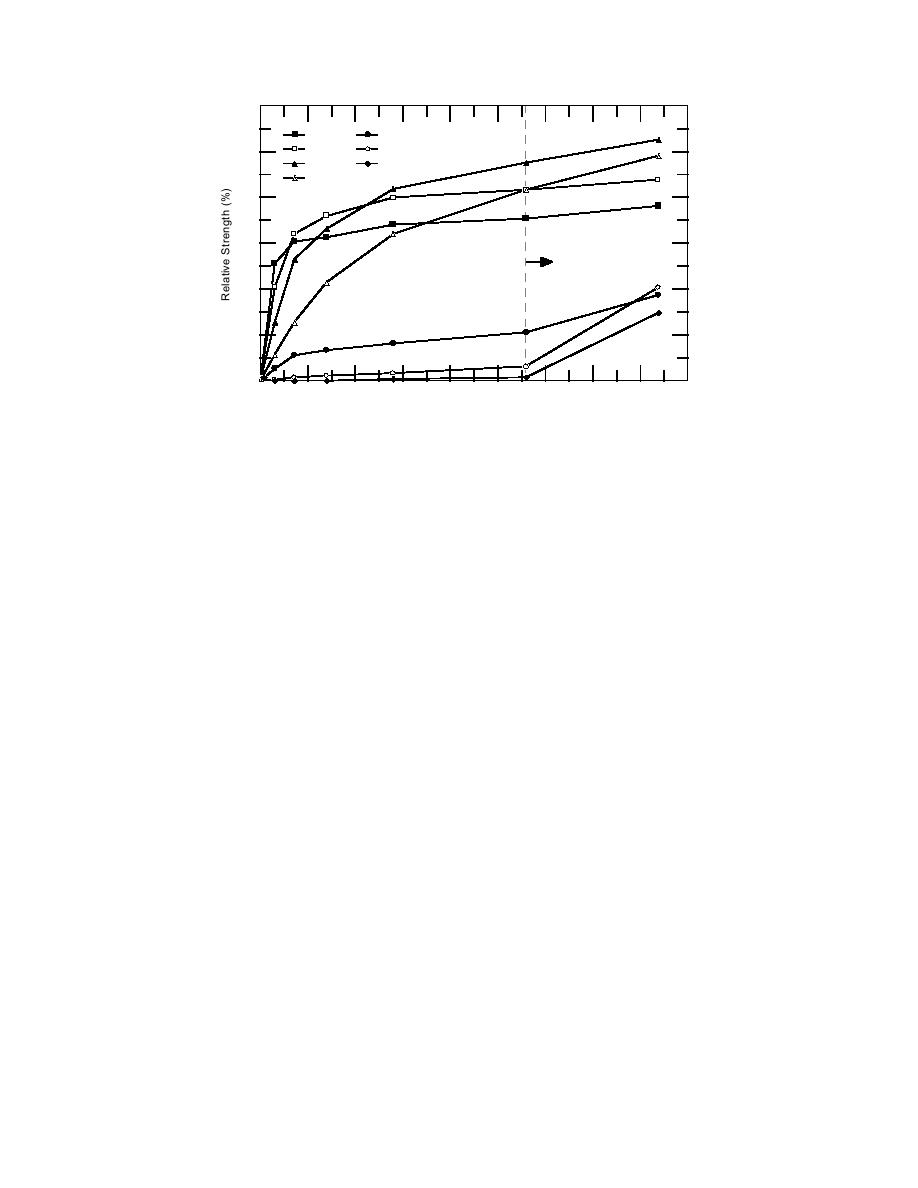

150

40C

5C

20C

10C

125

10C

20C

5C

100

75

20C Cure

50

25

0

0

10

20

30

40

50

60

70

80

90

Days

Figure 1. Effect of temperature on strength gain of normal concrete. All

strengths are referenced to the 28-day strength of the 20C concrete. The 40, 10

and 5C lines are based on relations presented by ACI. The other data are from

laboratory tests at CRREL.

lion every year on measures to protect fresh con-

Also, we decided that the initial low-tempera-

ture goal would be 5C, with 10C or perhaps

crete from freezing (Civil Engineering 1991).

20C being the ultimate objective, and that the

concrete cured at this low temperature should

Antifreeze admixtures

gain strength at least as rapidly as normal con-

Antifreeze admixtures are chemicals that

crete cured at 5C.

depress the freezing point of water and acceler-

Numerous chemical mixtures were investigat-

ate the hydration of cement. The literature cites

ed before one prototype formulation from each

numerous chemicals that can function as acceler-

company was selected for final testing: EY11

ators, calcium chloride being the most popular.

from Master Builders, Inc., and DP from W.R.

And there are many common substances that

Grace & Co. Because the admixtures are proprie-

dissolve in water and can serve as freezing point

tary, the chemicals used in them are not dis-

depressants. The challenge, however, is to find

closed.

chemicals that will work together and that will

Data from nearly two years of laboratory test-

not harm the concrete.

ing have not proven that the prototype admix-

Because no standards or acceptance criteria

tures harm the concrete. The concrete made with

are available for antifreeze admixtures, it was

necessary at the start of the CPAR projects to

each admixture passed standard freezethaw

tests, did not shrink excessively, did not contain

define such criteria. An antifreeze admixture

excess alkalis, and did not promote corrosion.

should:

Further, the admixtures promoted strength in

Depress the freezing point of water.

concrete cured at 5C that exceeded the strength

Promote strength gain of concrete at low

attained by normal concrete cured at 5C. The

temperatures.

Not interfere with concrete strength gain at

prototypes were ready for field evaluation.

normal temperatures.

Maintain the workability of the concrete.

FIELD EVALUATION

Achieve a reasonable concrete set time.

Produce freezethaw durable concrete.

Soo Locks

Not react with silica aggregate.

The Soo Area Office was replacing 39 sections

Not corrode steel.

of concrete that showed advanced freezethaw

Not adversely alter hydration products.

deterioration. They devoted four reinforced

Be cost effective.

slabs on grade, measuring 5.5 m wide by 6.1 m

2

Previous Page

Previous Page