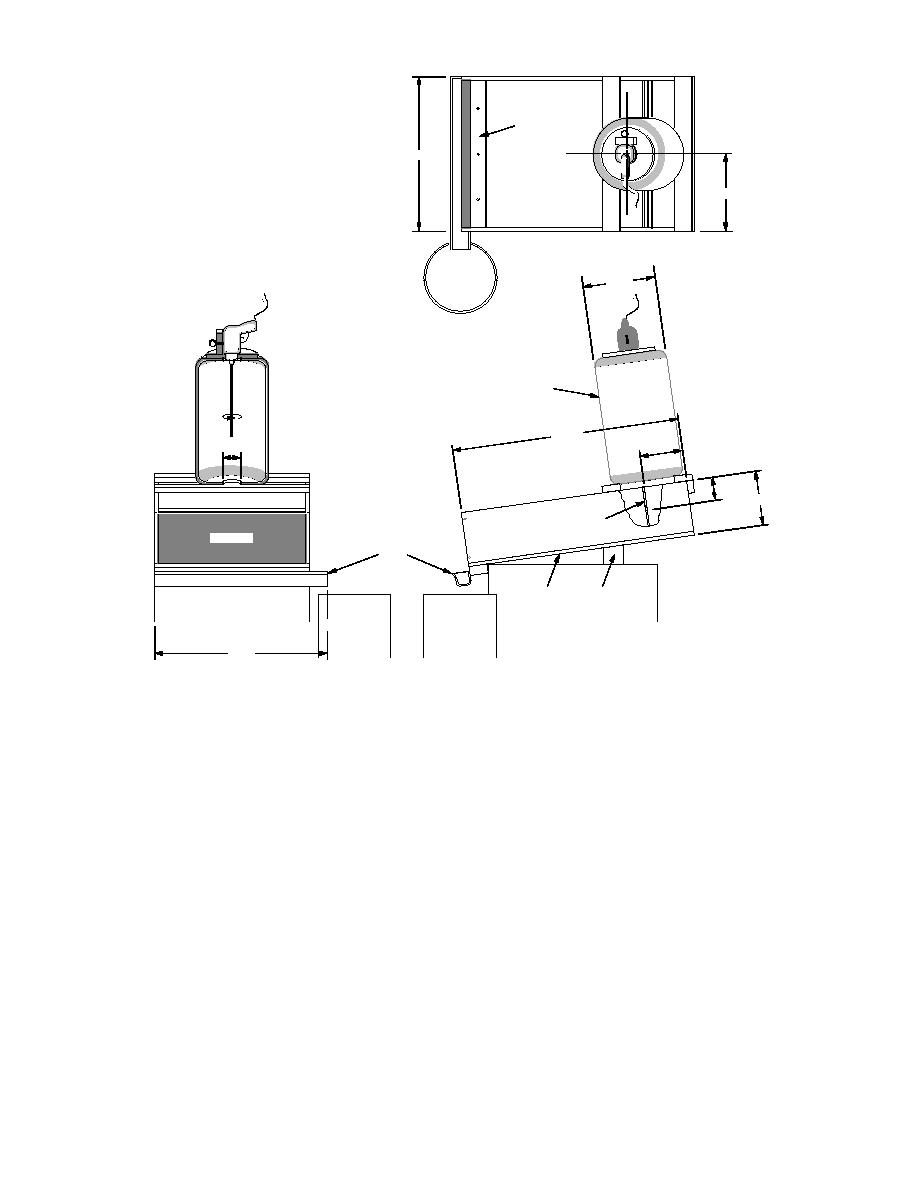

Steel Plate (with

countersink screws)

85 cm

42.5 cm

Top View

75-L Plastic

or Nonmetallic

40 cm

Container

Drill

75-L Plastic

or Nonmetallic

Container

Stirrer

125 cm

23.5 cm

10 cm

13 cm

30 cm

Gate for

Part II

Geotextile

Tests

Aluminum Gutter

8% Grade

Wooden Block

75-L Plastic

75-L Plastic

or Nonmetallic

or Nonmetallic

Container

Container

95 cm

Front View

Side View

Figure 4. Diagram of flume used to conduct silt fence tests.

2) The soilwater mixture was released into

available from Forestry Suppliers, Inc., Jackson,

the flume immediately after one minute of

Mississippi.

agitation (i.e., agitation was not continued

during the release).

Part I

3) Rather than taking one depth-integrated

Twelve tests were conducted in Part I; there

sample, three samples of soil-laden water

were three replications for each of four geotextiles,

using a PVC Coliwasa water sampler were

tested in random order. The initial TSS of the sedi-

taken and analyzed independently for TSS.

ment-laden water released to the flume was ei-

Each sample was approximately 50 mL.

ther 2830 mg/L or 2880 mg/L, depending on how

In test 2, the back of the geotextile was scraped

much rinse water was used after the mixture was

with a spoon about 15 minutes after the test was

released. The procedure described in ASTM D 5141

begun and a significant increase in the instanta-

(1992) was followed, with three minor adjust-

neous flow rate of water through the geotextile

ments, listed below:

was noted. This procedure probably resulted in

1) In order to break apart aggregated soil par-

an increased amount of sediment passing through

ticles, the soil was mixed in a blender with

the geotextile and is discussed further in a later

500 mL of water before being added to the

section.

rest of the water.

4

Previous Page

Previous Page