10

8

6

4

2

0

5

10

15

20

Applied Axial Strain (%)

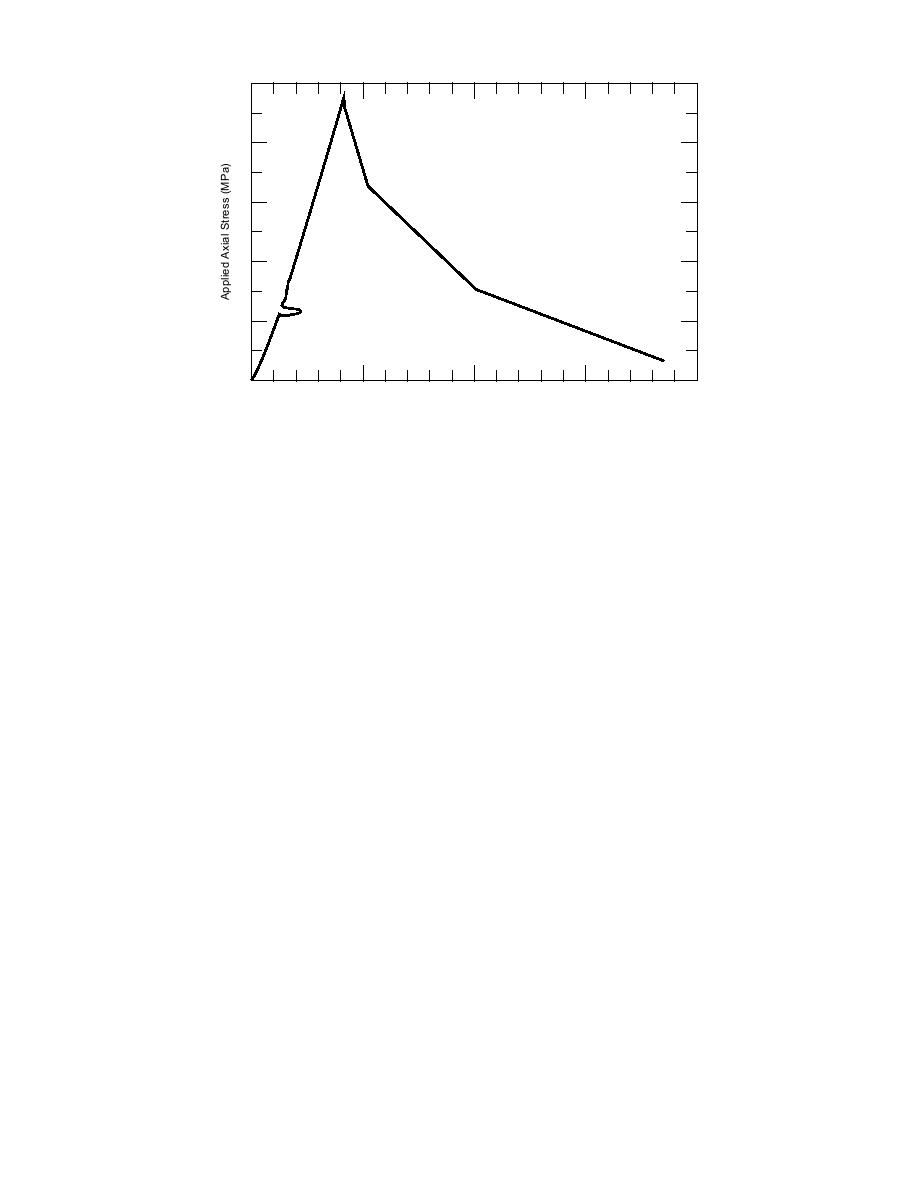

Figure 6. Stressstrain curve from ice at a depth of 10.515.5 cm, extracted at the

south end of the runway (10,000 ft). Applied loading rate was 44.5 kN/s.

The results of unconfined compression tests on

(U.S. Army and Air Force 1968). A more rigorous

a few Pegasus runway ice core samples are shown

approach, specifically for glacial ice, should fol-

in Figures 6 and 7 (more information can be found

low the system developed within the USAP for

in Lang and Blaisdell, in prep.). Most of the core

determining suitable floating sea ice thicknesses

samples were not suitable for testing since the

to assure that the anticipated aircraft loads can be

supported during landing and parking (Barthel-

cores shattered during the coring process. Few

emy 1992).

specimens with adequate length for compressive

At the Pegasus runway, initial coring revealed

tests were available. The tested samples were ex-

two very distinct ice types and several discontin-

tracted at the south end of the runway. Unfortu-

uities. The uppermost ice layer throughout parts

nately, this is not the location of the weakest

of the region is glassy, bluish in color, and in-

meltwater ice.

cludes many parallel, long, cylindrical bubbles

Figure 6 shows the stressstrain curve from ice

(Fig. 4). This ice suggests at least one cycle of

at a depth of 10.515.5 cm from the south end

melt/refreeze behavior. Ice samples from lower

core; this is snow derived ice (i.e., glacial ice). The

in the core are cloudy with a milky white hue

applied loading rate was 44.4 kN/s (10,000 lbf/s).

(Fig. 5). The enclosed bubbles make up a larger

This rate represents the approximate loading rate

volume fraction but are spherical in shape and

of a C-141 tire rolling at 1.7 km/hr (1 mph). The

test temperature was 10C. Figure 6 shows a

range in size from 1 to about 5 mm. This ice is

typical of glacial ice formed by natural consolida-

clear linear relationship between stress and strain

tion of snow. In most cores, the contact between

to failure. This is indicative of a brittle failure

the two ice types is sharp but firmly bonded, but

mode in the ice. The failure stress is approxi-

a thin gap was occasionally detected (by probing

mately 10 MPa (1450 psi).

down in the core hole). This gap was about 5 mm

The test results in Figure 7 are for an ice sample

thick and contained hoar (faceted) crystals on both

located lower in the horizon (2027 cm deep). Its

surfaces. Examination of the ice cores in meltwa-

failure strength is approximately one-third of the

ter ice revealed that the ice contained many large

strength of the sample that was closer to the sur-

cracks. The ice exhibited failure planes that sug-

face. This may be a result of grain size effect;

gested doming and radial (star-like) pattern sur-

grain size increased with depth at the south end

face fractures. These features are probably the

of the runway. The larger grain size could ac-

result of natural processes (discussed later).

count for the reduction in strength. Figure 7 also

7

Previous Page

Previous Page