of view of the video camera limited our ability to

shorter length scales). Associated with most sculp-

maneuver the collector. We tried several tech-

tured features were dark pockets of particulates.

niques, unsuccessfully, to orient the camera to fol-

Particles on the plateau areas were visible but not

low the collector.

concentrated into pockets. Local surface roughness

The spiked wheels, often doubled on each end,

was quite smooth (perhaps 1-mm depressions over

provided extremely good traction on the ice. The

15 mm scales). For this reason, we did not use

allowable motor torque, rather than traction,

the Teflon-wire runners or external LDPE flap

generally limited collector maneuverability on

(developed for very smooth or rough ice, respec-

steep sections, although collector stability was also

tively).

a factor. We normally worked around these limi-

The collector maneuvered easily over the cen-

tations quite successfully, and could have substan-

tral plateau, and we devoted one collection (no. 3)

tially increased the area suctioned within the per-

exclusively to the plateau. Movement onto the ad-

formance capabilities of the 1.2-m collector. Un-

joining dips and plateaus was possible with some

fortunately, after about two hours of maneuver-

practice, and we collected from five of these (about

10 m2 total), including three particle pockets. We

ing during a deployment, the drive motors failed.

Post-deployment inspection revealed that shear-

collected as much as 50 g of material at once

ing of gear teeth in each motor's gearbox caused

without appreciably reducing pumping efficiency.

the failures. This repeatedly occurred, despite

Plateau areas suctioned were visibly clean, and

readouts from the drive-motor power supplies that

gently curved dark areas changed from black to

indicated operation at about half of the continu-

white with a single pass. This indicated high-effi-

ous-duty torque rating provided by the motor

ciency particle pickup, based on our laboratory ex-

manufacturer. After all four motors had failed once

perience.

(by deployment no. 4), we continued to run the

Good contact between the collector bottom and

collector by interchanging gears between gear-

the ice surface was the most serious limit to col-

boxes; this provided us with about two hours of

lection efficiency in severely curved areas, and we

operation before motor failure for deployments 5

maneuvered the collector slowly across the asso-

and 6.

ciated pockets to maintain good surface contact.

We had planned to dedicate deployment no. 4

This technique worked well but was very time-

to repeat suctioning of the central plateau. This

consuming. During some deployments, the field

would have allowed us to calculate in-situ collec-

tion efficiency. Unfortunately, one drive motor

failed at the start of that deployment, and we only

covered about one third of the central plateau.

Upon retrieval of the collector, we found very little

material in the filter bag and decided to reuse it

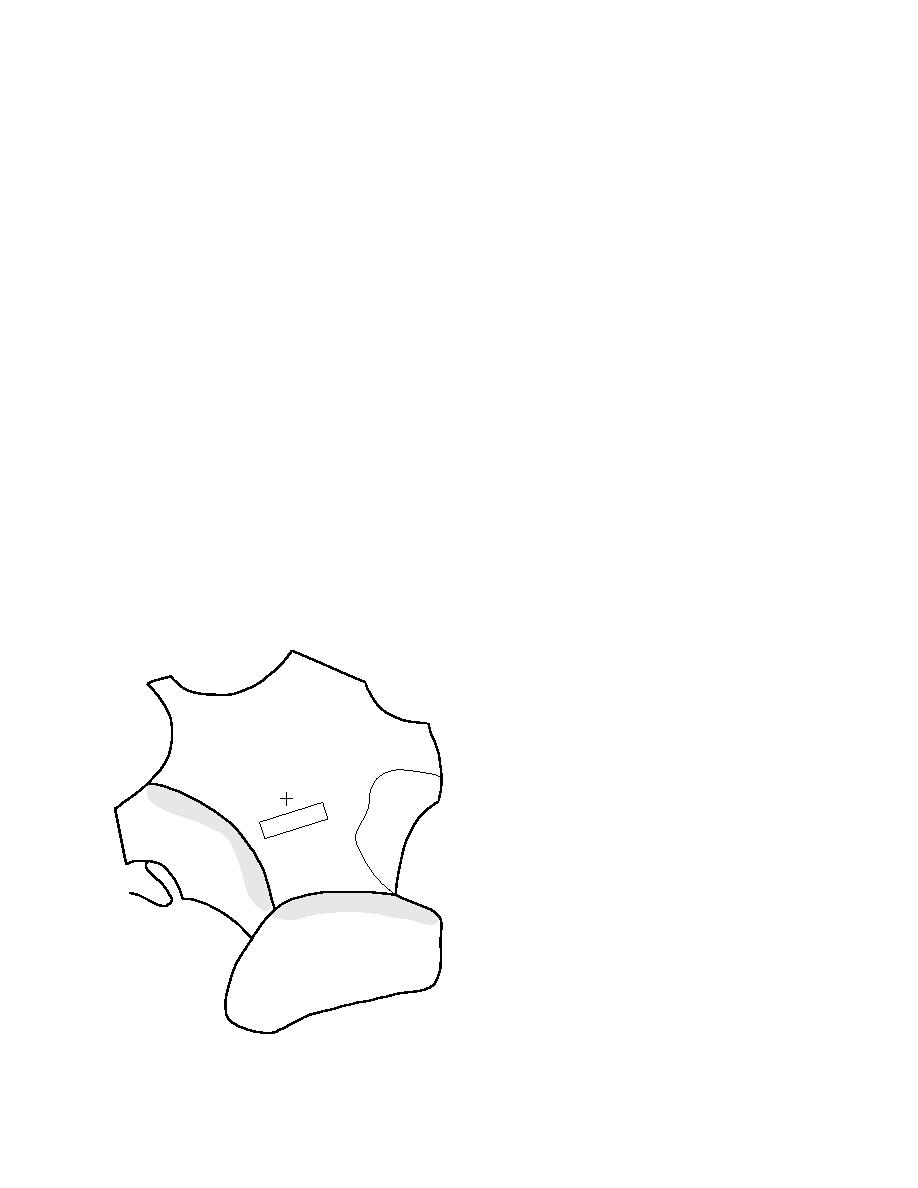

Plateau

for the next deployment to save time. Although

not quantitative, the results of deployment no. 4

and the visually apparent cleaning of particles

from the ice suggests a high in-situ collection effi-

r

ecto

ciency.

Coll

Pocket 1

SAMPLES

After each deployment except no. 4, we brought

the collector to the laboratory space and removed

Pocket 5 and 6

the polyester filter from the filter arm. The white

flexible fabric allowed us to see particles and eas-

ily remove them by backflushing the filter. We

backflushed each of the two samples we processed

into a large HDPE funnel, using well water that

we pressurized in an HDPE hand sprayer. Each

sample, one from a pocket, the other from the pla-

Figure 12. Map of the bottom of the SPWW showing

teau, was then wet-sieved into stainless steel sieves

the plateau area and pocket no. 1.

15

Previous Page

Previous Page